14

2025.1

author

154

Reading volume

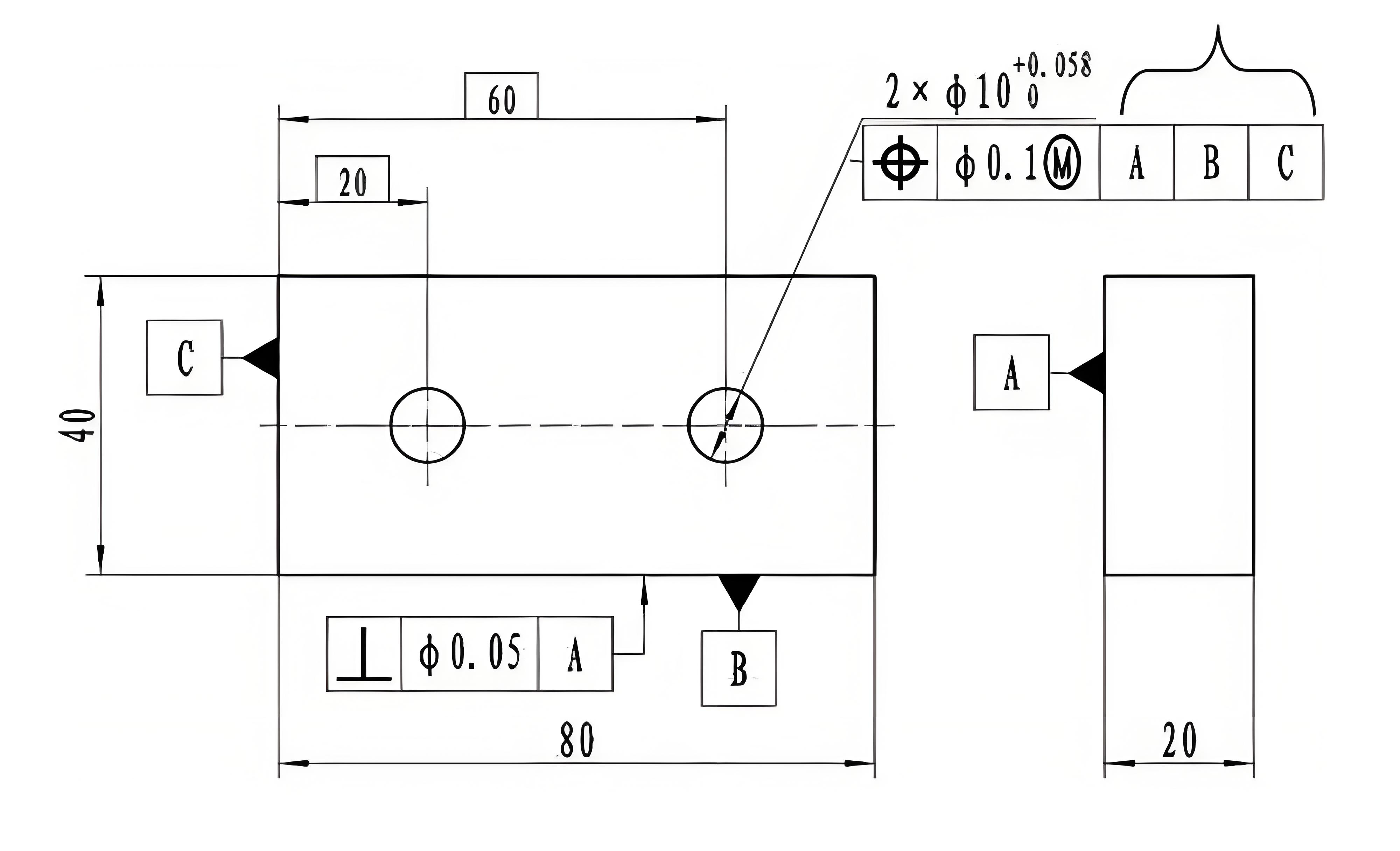

1. Meaning of the benchmark

• In the process of product design, manufacturing, assembly and testing, the points, lines and surfaces are used as the basis on the part drawing, process drawing and assembly drawing.

Very important: all benchmarks in the work process should be uniform!

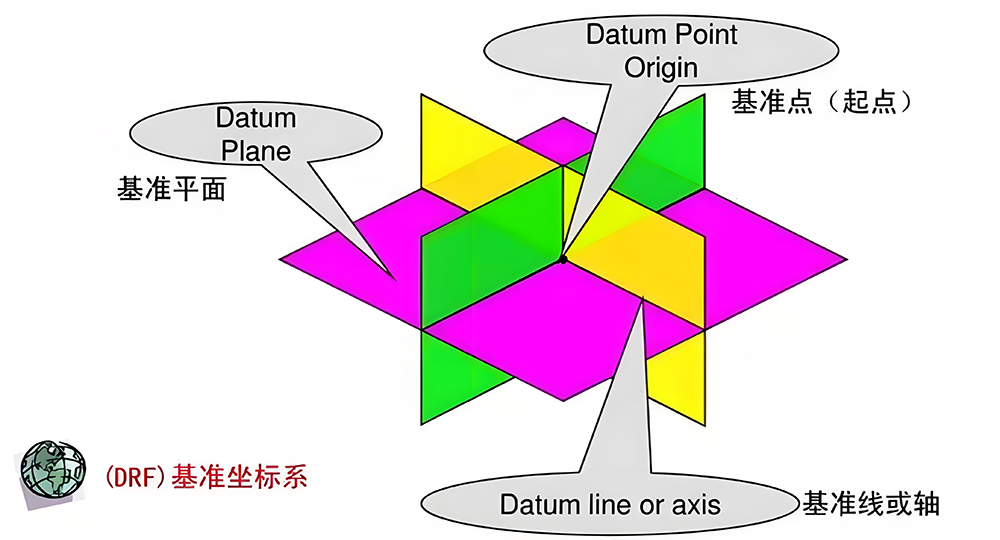

TwoMeaning of the reference system

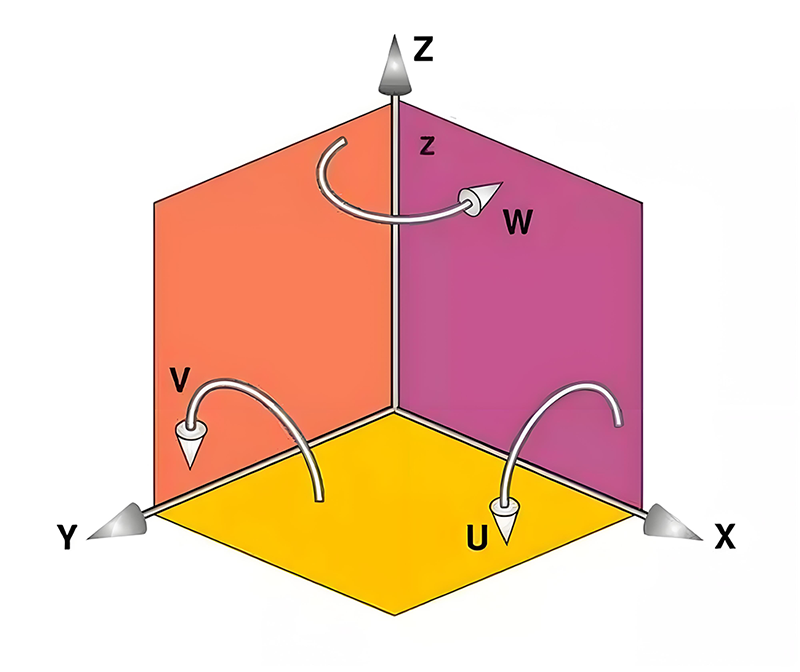

• The Datum ReferenceFrame (DRF) consists of three planes perpendicular to each other, providing a starting point for position and orientation measurements

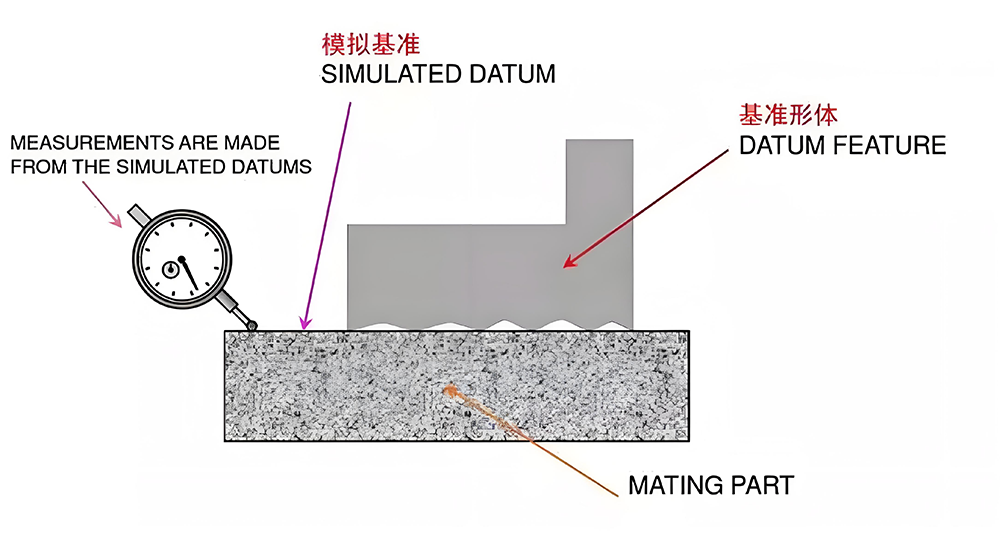

ThreeBenchmark body meaning

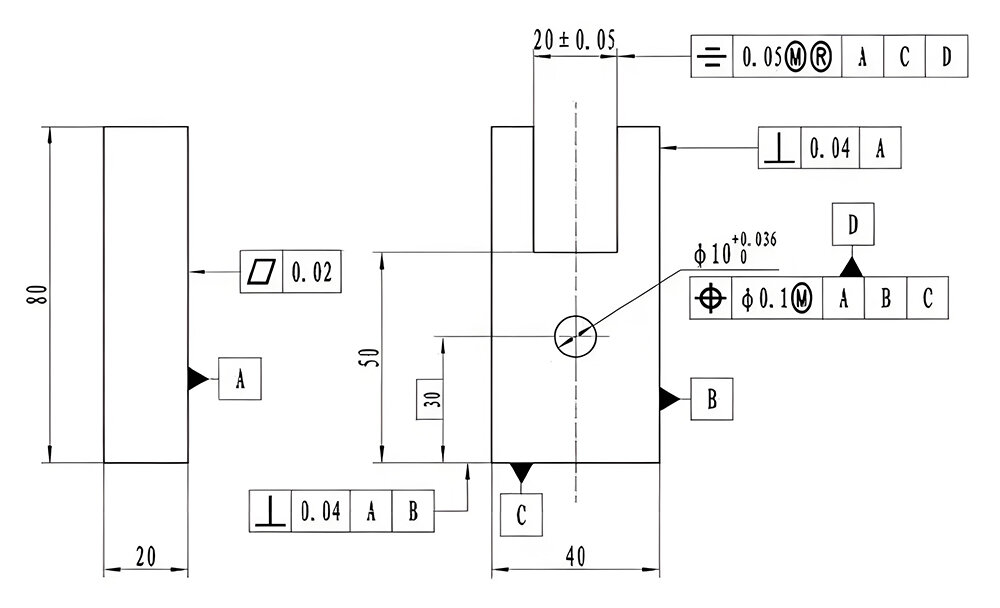

• The shape on the part that is used to establish the datum, and the datum shape is on the part.

• The role of the datum shape: The datum is used to establish the datum system (DRF) and is represented by letters in the body control box.

FourSix constraint positioning principles of the workpiece

•Note:

(1)When positioning the support point restricts the degree of freedom of the workpiece, the supporting point must always be closely attached to the positioning datum of the workpiece.

(2) A support point only restricts one degree of freedom of the workpiece, and the same degree of freedom of the workpiece can only have one support point limit;

(3) Clamping ≠ positioning

FiveReference symbols and callouts

•Note:

Letters must not be usedE I J M O P L R F("Tolerance Coordination and Measurement Technology", Huang Yunqing Machinery Industry Press, April 2005)

The letters are in a sequential order (GB/T1182-2008 "Geometric Tolerance Shape, Direction, Position and Runout Tolerance Labeling" 9.5In the national standard GBIT 1183-1996, the reference symbol is