15

2025.3

author

156

Reading volume

"A good horse with a good saddle" is known to everyone, and the use of good tools in CNC machining is a crucial condition. In the ever-changing world of machining, tool manufacturers are constantly introducing innovative cutting tools and solutions.SandvikAs a benchmark enterprise in the tool industry, what new tool technologies have Coloman recently released? Learn about these new technologies that can help improve your mill's machining skills, and today we will introduce you to some of the new Sandvik Coroman tools.

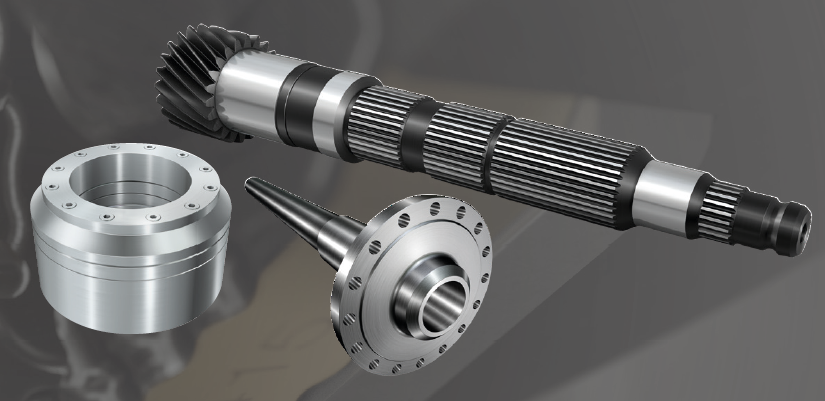

A new rail interface is now available for round blades and tool holders. With fixed insert indexing, you can ensure that the insert is indexed in the same way every time and improve the quality and productivity of profiling and cavity machining processes. The new CBN platform features screw-mounted blades and up to 12 blade indexes available, which will increase productivity in heat-resistant superalloy materials.

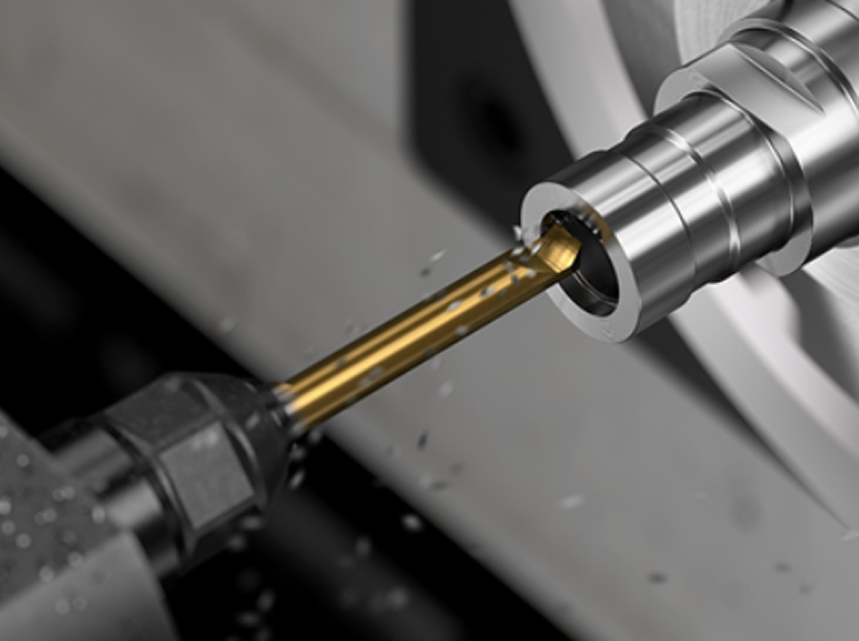

The CoroMill® Plura HFS 5×D is a new carbide end mill designed for titanium cavity machining with tool lengths up to 5 times the diameter. With its innovative "shape control" design, end mills are ideal for stable machining of tall and thin walls without bending, while still achieving excellent surface quality.

• Innovative patented geometry with helix angle depending on the depth of cut

• Tapered core for increased tool rigidity

• Corner radius for titanium machining

• Unequal pitch for high speeds (up to 230 m/min)

• Equipped with 1745 material to optimize the roughing of titanium alloys

• Axial bore coolant and chip breaker for safe chip evacuation

• With lengths up to 5 times the diameter, this end mill can machine grooves in a single high-feed side milling step while avoiding misalignment, saving time and increasing productivity

• The "shape control" design ensures reduced bending, maximum stability and excellent surface quality for improved machining safety and tool life

• One integral end mill for both roughing and finishing can reduce inventory footprint Innovative features

• Innovative patented geometry with helix angle depending on the depth of cut

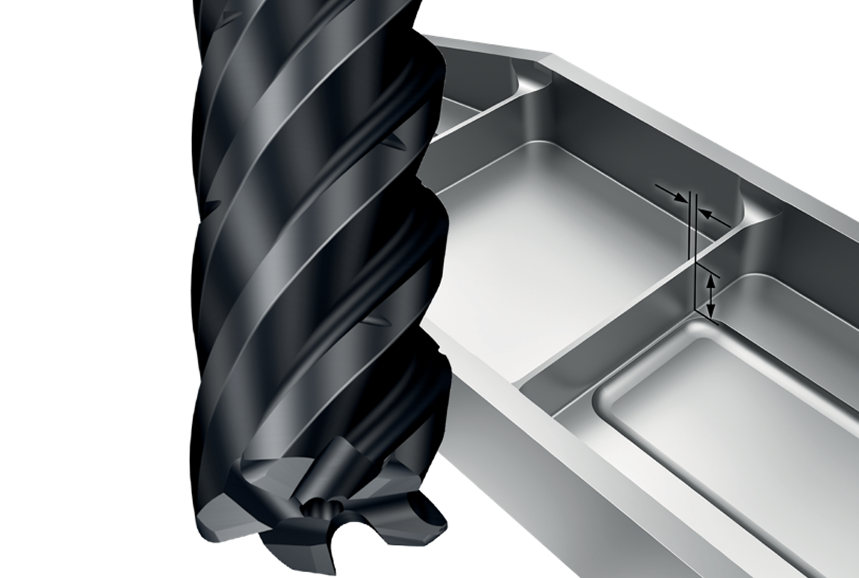

The CoroMill® Plura Gannet is a monolithic end mill developed specifically for slot milling in heat-resistant superalloys. This end mill is part of Sandvik's Coromant-specific product range and is ideal for heat-resistant superalloy aerospace monolithic blades that are roughed using plunge milling. End mills equipped with excellent wear-resistant 1610 material have high process safety and long tool life.

• Robust, patented geometry specially designed for insert milling

• Equipped with 1610 material, optimized insert milling of heat-resistant superalloys

• Cooling grooves on the tool handle for safe chip evacuation

• Provides excellent deformation control

• Delivers superior productivity and tool life

• Unique solution for high productivity of parts with closed slots (e.g. closed monolithic blade grooves).

• Extremely high productivity due to the ability to cut large depths of cut in a limited time

• Since the force direction is axial, the self-stabilization effect is optimized

• Balanced anterior slot with ae = 30% ×DC

• Long overhang machining is possible, specifically designed for plunge milling